Stock Code: 003027

English

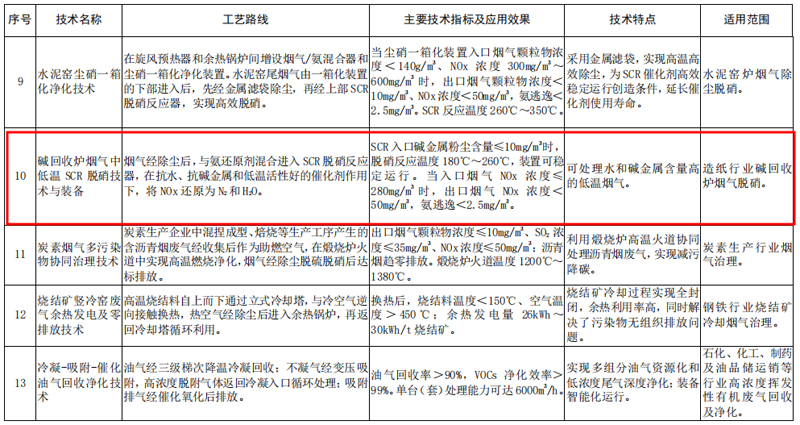

Recently, the Ministry of Ecology and Environment announced the National Catalog of Pollution Prevention and Control Technologies (Encouraged Category). TONEXUS Technology's "Low-Temperature SCR Denitrification Technology and Equipment for Alkali Recovery Boiler Flue Gas" was successfully selected as a national demonstration technology for pollution prevention and control. According to the Catalog, demonstration technologies possess innovativeness, advanced technical indicators, have reached the level of practical engineering application, and hold demonstration value for projects.

TONEXUS Technology's Low-Temperature SCR Denitrification Technology and Equipment for Alkali Recovery Boiler Flue Gas, evaluated and certified by a panel of experts organized by the China Association of Environmental Protection Industry, has successfully solved the challenges associated with the pulp and paper industry's alkali recovery boiler flue gas, including low temperature, high humidity, and high alkali metal content. The technology reaches the world-leading level and fills a gap in the domestic market.

The process route is as follows: After dedusting, the flue gas is mixed with the ammonia reductant and then enters the SCR denitrification reactor. Under the action of a catalyst characterized by water resistance, alkali metal resistance, and good low-temperature activity, nitrogen oxides (NOx) are reduced to nitrogen gas (N₂) and water (H₂O). This technology is applicable for denitrification of flue gas from alkali recovery boilers in the pulp and paper industry.