Stock Code: 003027

English

In the era of the “Dual Carbon” goals, the focus of industrial enterprises on denitrification systems is undergoing a clear shift.

The question is no longer simply whether emission standards can be met, but whether systems can operate stably over the long term, whether total costs are controllable, and whether normal production rhythms are affected.

In real-world operation, many enterprises have found that under conditions of temperature fluctuation, high-sulfur flue gas, and long-term operation, traditional SCR catalysts often require frequent adjustments, frequent replacements, and repeated investment—gradually turning denitrification into an unavoidable “hidden cost.”

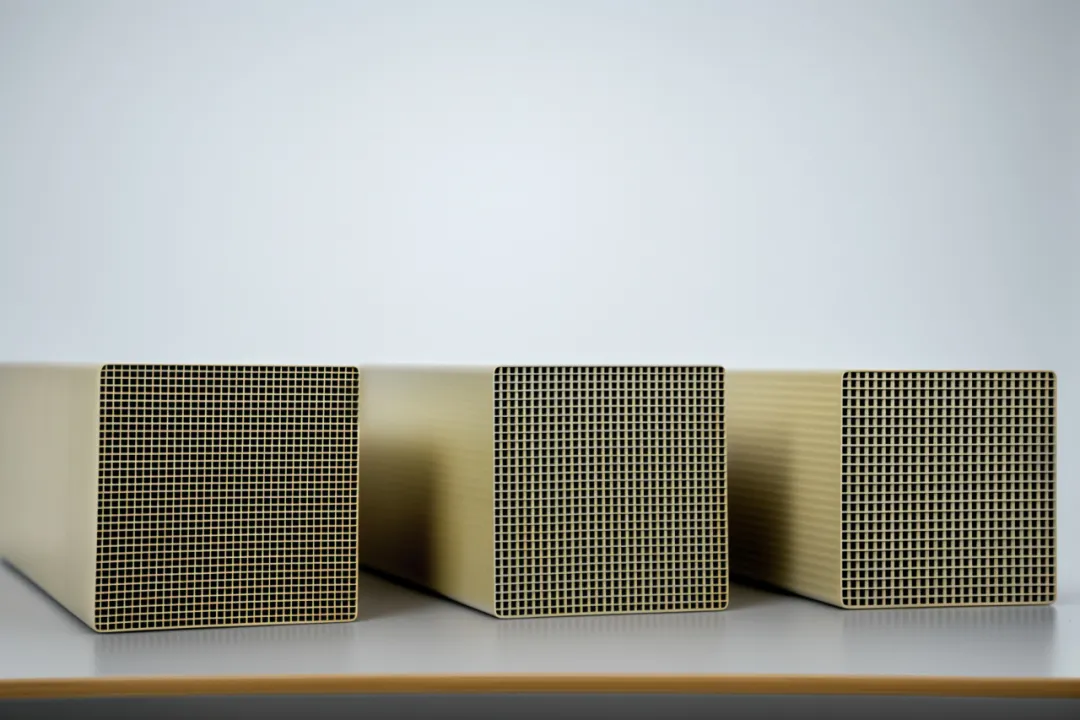

Drawing on decades of flue-gas treatment engineering experience, TONEXUS has launched a wide-temperature-range SCR catalyst. Through three major “technological revolutions,” it helps customers transform denitrification systems from “high-risk operating units” into stable, predictable cost units.

I. Wide-Temperature Revolution: True Wide-Range Operation at 150–350°C

In many industries—such as steel, chemicals, glass, and cement—frequent start-ups and shutdowns, along with highly fluctuating operating conditions, keep SCR systems operating outside standard temperature ranges.

The active temperature window of conventional catalysts is typically limited to 220–320°C. Once temperatures deviate from this range, efficiency fluctuations occur, or production conditions must be forcibly adjusted.

Based on its proprietary formulation system, TONEXUS wide-temperature SCR catalysts achieve an ultra-wide operating window of 150–350°C:

* Temperature fluctuations no longer directly affect denitrification efficiency

* Rapid start-up at low temperatures with stable activity in high-temperature zones

* Suitable for both new installations and retrofit projects, with flexible switching across different operating conditions

This breakthrough enables wide-temperature catalysts to deliver higher operational adaptability in industries with frequent start-ups and shutdowns, such as steel, coking, and waste incineration.

Customer Benefits

* Elimination of gas preheating units (accounting for approximately 15% of total investment)

* Reduced downtime and adjustment losses caused by temperature mismatch, ensuring production continuity

II. Sulfur-Resistance Revolution: From “Easily Poisoned” to “High-Sulfur Immune”

High-sulfur fuels, wet flue gas, and alkali metals (K/Na) are the primary causes of catalyst deactivation.

Across the industry, issues such as sulfate blockage in catalyst pores and coverage of active sites are common, often requiring catalyst replacement within about six months—resulting in high costs and unstable operation.

The new-generation SCR catalyst from **TONEXUS** adopts a dual structure combining sulfur-repellent coating and poison-resistant support, significantly enhancing sulfur resistance and overall anti-poisoning performance:

* Maintains over 90% denitrification efficiency under high-sulfur flue-gas conditions

* Strong resistance to alkali and alkaline-earth metal poisoning (e.g., recovery boilers in the pulp and paper industry)

* Better suited for complex operating conditions involving high humidity, high alkalinity, and high dust loads

Customer Benefits

* Extended service life: replacement cycle increased from 8 months to 4 years

III. Energy-Saving Revolution: 30%–60% Reduction in System Energy Consumption

Under the same denitrification efficiency, **TONEXUS wide-temperature SCR catalysts** achieve system-level energy savings through optimization of material systems and pore structures:

* Lower reaction activation energy, reducing ammonia consumption

* Reduced system pressure drop, lowering fan power consumption

* Extended catalyst lifespan, reducing repeated investment

Wide-temperature operation eliminates the need for additional heating devices and avoids efficiency losses caused by insufficient temperatures, resulting in a significant reduction in overall energy consumption.

Customer Benefits

* Sharp reduction in energy use: fan power consumption reduced by approximately 40%, delivering substantial long-term electricity cost savings

* Carbon cost optimization: approximately 1.2 tons of carbon allowance saved per 10,000 tons of flue gas

* Cost reduction: for a paper mill with a flue-gas flow rate of 200,000 Nm³/h, annual electricity savings reach RMB 480,000, with ROI of less than two years

IV. Industry Validation: Reliability Backed by 800+ Engineering Projects

TONEXUS wide-temperature SCR catalysts are operating stably in more than 800 engineering projects nationwide, covering steel, waste incineration, cement, chemicals, glass, and other industries.

The value of these projects lies not in showcasing technical parameters, but in demonstrating proven reliability under complex operating conditions—helping customers reduce trial-and-error costs and avoid systemic risks associated with solution failure.

Customer Benefits

* Proven operating conditions available for direct reference, reducing uncertainty in project selection

* High level of engineering maturity, minimizing the risk of secondary retrofits and rework

* Clear operation and maintenance models, facilitating long-term cost calculation and management

Conclusion: The Wide-Temperature Era Calls for More Advanced SCR Solutions

As environmental standards continue to tighten and operating conditions grow increasingly complex, traditional catalysts can no longer support enterprises’ needs for stable compliance.

TONEXUS will continue to focus on material innovation, driving SCR catalysts from merely “adapting to operating conditions” toward “leading operating conditions.”

Wide temperature—for greater freedom in denitrification.

Sulfur resistance—for greater system stability.

Energy efficiency—for more economical environmental governance.

We look forward to working with you to build a more efficient, lower-carbon industrial future.