Specialist in Low Temperature

Flue Gas Treatment

20 years of experience in flue gas DeSOx,

DeNOx and DeDust – Together, we shape a net-zero industrial future.

Wide Range of

Industry Applications

700+ Cases

Rich Process

CompositionProvide

Customized Services

Low Investment

and Operating Costs

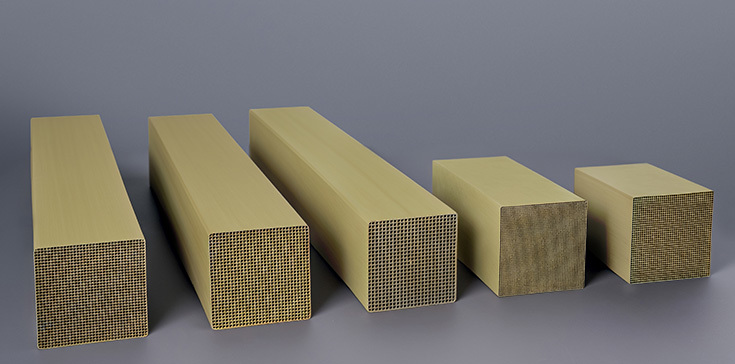

Low-temperature

SCR Catalysts

Technology Leadership

In-house R&D Center

Personalization of

Catalyst Formulations

20 Years of Experience in Low Temperature

Flue Gas Treatment

Rich Industry Flue Gas Treatment Cases

The project footprint covers more than 20 industries such as steel, building materials, paper, power, etc., with a total of more than 700 sets of cases worldwide.

2500 tds/d Alkali Recovery Furnace Flue Gas Denitration Project

· The Low-Temperature SCR Denitration Technology and Equipment for Alkali Recovery Furnace Flue Gas was appraised by CEIA as reaching the internationally leading level.

Jinlong Pulp Alkali Recovery Furnace Flue Gas Ultra-Low Emission EPC Retrofit Project

· The desulfurization by-product is recyclable for the alkali recovery process.

RB2-7500tds/d Alkali Recovery Furnace Flue Gas Low-Temperature SCR Denitration Project

· Simple, stable equipment;low operating cost;easier later maintenance

Coke Oven Flue Gas Purification Facilities EP Project, Integrated Dedusting and Denitration System

· Help the client avoid risks such as fines and production restrictions due to non-compliance with environmental regulations.

2×600 t/d Lime Kiln Denitration Project

· Adopt the Tongxing Twin-Shaft Lime Kiln Flue Gas Specific Denitration Catalyst, realizing efficient and stable denitration at medium-low temperatures of 195~220°C in the presence of sulfur.

4#660m² Sintering Flue Gas Low-Temperature Denitration Project

· Adopt the Tongxing Sintering Flue Gas Specific Denitration Catalyst, realizing efficient and stable denitration at 180°C low temperature after passing through activated carbon adsorption desulfurization.

15 Units Biomass Boiler Flue Gas Denitration Project

· The equipment is simple, stable with low operating costs, and low-temperature denitration thereby increases the boiler's waste heat recovery.

Desulfurization Technical Retrofit Project for No.2 & No.3 Boilers at Power Plant No.3 in Liugang Power Plant (2 * 55MW Gas-Fired Power Generation Boilers)

· Adopt dry desulfurization technology, featuring simple and stable equipment, low operating costs, and simpler post-maintenance.

SCR Catalyst Supply Project for Ningbo Waste Incineration Plant

· First application of Chinese Low-Temperature SCR Catalyst in the waste incineration industry; First replacement of imported catalyst with Chinese Low-Temperature SCR Catalyst in the waste incineration industry.

Environmental Project for Flue Gas Denitration in the First Alumina Plant Clinker Kiln

1# & 2# Chromate Rotary Kiln Flue Gas Denitration (EP)

· The equipment is simple and stable with low operating costs and simpler post-maintenance.

Alumina Sintering Furnace Medium-Low Temperature SCR Denitration Project

· Annual Nox emission reduction: 293.46 t/year ~ 416.1 t/year.

Glass Kiln Low-Temperature SCR Denitration Project

· Denitration efficiency reaches 38.3%, featuring low operating costs and simpler post-maintenance.

Ceramics Low-Temperature SCR Denitration Project

· Denitration efficiency reaches 80%, featuring low operating costs and simpler post-maintenance.

Chemical Incineration Low-Temperature SCR Denitration Project

· Adopting low-temperature SCR denitration catalyst, the equipment is simple and stable, does not require heating, and features low operating costs and simpler post-maintenance.

Low-temperature Flue Gas Purification Engineering Expert

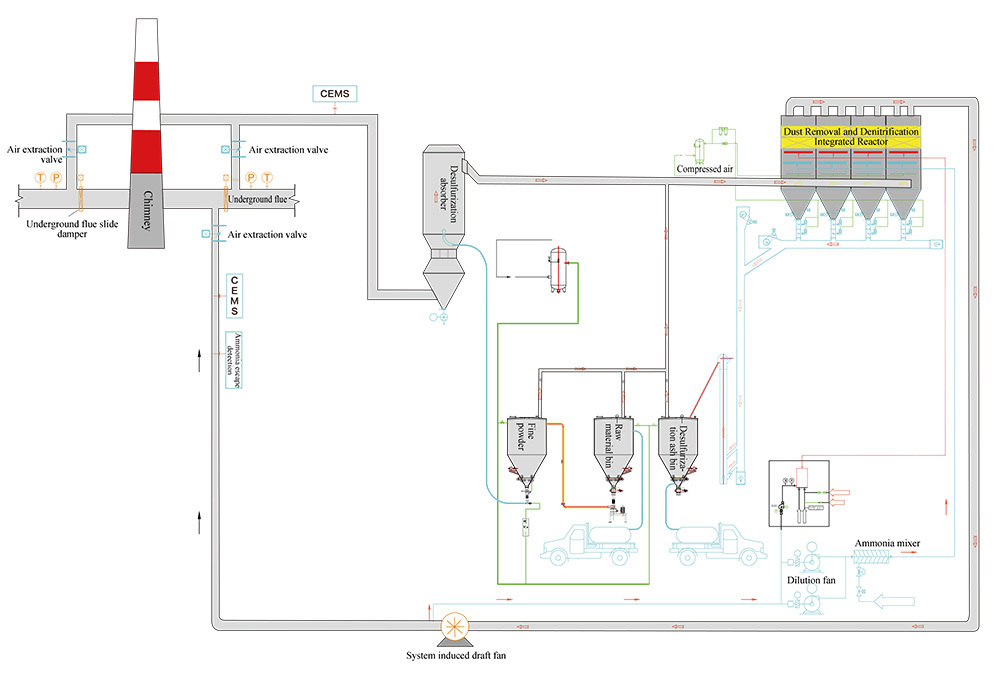

Comprehensive Process Technology, Rich Portfolio, and Near-zero Emissions

With the combination of low-temperature SCR, desulfurization, and dust removal integrated process, it can realize multi-pollutant co-efficient and simultaneous treatment, covering many high pollution industries such as iron and steel, coking, paper making, etc., and realizing ultra-low emission.

Diverse Cooperation Modes, Professional & Efficient Services, Concurrent Emission Reduction, Energy Conservation and Carbon Reduction

Provide EPC turnkey services, product supply, operation and maintenance, contract energy management and other service modes, with the ability to design, supply, installation, commissioning, training and other full-process services, to achieve emissions reduction and energy saving and carbon reduction synchronized landing.

20+Industry Coverage, 700+Sets of Project Cases

The project footprint covers a wide range of industries such as steel, building materials, paper and so on, with a total of more than 700 sets of cases nationwide and overseas, accumulating a wealth of experience.

Leader in Low-temperature SCR Catalysts

Tongxing Low-temperature SCR Catalyst 5 Big Performance Advantages

- Significant low-temperature high activity (150-160°C, ≥80% efficiency; 160-400°C, ≥90% efficiency)

- Strong resistance to sulfur poisoning, alkali metal poisoning properties

- Excellent hydrophobicity

- Highly efficient synergistic removal of dioxins

- With obvious advantages of energy saving and consumption reduction

National Green Factory--Creating an Energy Efficient Green Supply Chain System

Digital, Intelligent and Fully Automatic Production Base

Year of Environmental Equipment Production

Annual Production Capacity of Honeycomb-type Low-temperature SCR Catalysts

Annual Production Capacity of Coated Catalysts

Technical Research and Development

3 Large R&D Centers, More than 80 Authorized Patented Technologies

Tongxing has 3 R&D centers, more than 130 R & D team, equipped with more than 100 sets of high-end R&D test equipment, long-term investment in flue gas treatment, catalytic chemistry and other project research, has a wealth of R&D and innovation capabilities, has been a total of more than 80 authorized patented technologies.

A

InventionPatents

B

Utility Patents

- High cost of meeting emissions standards?

- Solving low temperature desulfurization and denitrification challenges?

- Tackling Tough Emissions Standards?

E·MAIL

PHONE

ADDRESS

Building B10, Binhu Financial Port,

Baohe District, Hefei City, Anhui Province