Carbon Capture,

Utilization and Storage Technology

Shaping the future of net-zero industry

and efficiently realizing the vision of carbon neutrality

Exclusive Carbon Capture

Absorption Solvent Antioxidant

Degradation Technology

Ultimate

Energy-efficient Design

Realize Green Production

CCUS

Customized Service

System

CO₂ Absorption Solvent

Purification and

Recovery Recycling

Low Concentration CO₂

Capture Technology

Carbon Capture, Storage and Utilization Application Difficulties

Degradable

In cases where gas sources such as coal-fired flue gas and lime kiln gas have complex conditions with relatively high oxygen content, conventional absorption solvent are prone to degradation and failure, resulting in a large amount of disposable waste liquid. This significantly increases the operating costs of absorption solvent and the treatment costs of waste liquid.

High Cost

Industries with high steam prices (> 200RMB/t), high energy consumption oftraditional absorption solvent (2.0t steam/t CO₂), and >70% of steam costs, eroding profits.

High Loss

Higher amine escape and conventional absorption solvent operating losses in regeneration. Solvent costs increased significantly.

Exclusive Carbon Capture Absorption Solvent Antioxidant Degradation Technology

The antioxidant degradation capacity of TX-1 absorption solvent is 20~300 times higher than that of MEA

Through countless trials and tests, we have put an end to the industry's degradation problems! The antioxidant degradation ability of TX-1 absorption solvent is 20~300 times higher than that of MEA. It is not degraded by regular oxygenation, which is the exclusive core technology advantage.

TX-1 absorption solvent regeneration energy consumption up to 2.1GJ/t CO₂

TX-1 absorption solvent regenetion energy consumption 2.1GJ/t CO₂, which reaches the international advanced level.

Low Concentration CO₂ Capture Technology

This technology can effectively handle low-pressure, low-concentration (5-30%) CO₂ sources, such as cement kiln gas, steel mill blast furnace gas, power plant flue gas, and so on, enabling efficient capture and resource utilization.

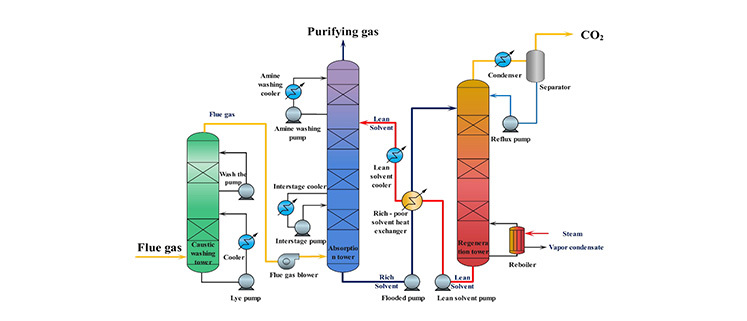

Ultimate Energy-efficient Design Realize Green Production

Highly efficient absorption solvent: Fast absorption rate, high loading, lowest regeneration energy consumption in the industry (< 1.0 t steam/t CO₂).

Extreme energy-saving design: Proprietary heat exchanger (end temperature difference of only 5~7K) + Regenerative latent heat recovery + High-efficiency reboiler (efficiency increased by 10-20%), realizing efficient utilization of heat energy.

Emission Reduction Guarantee: Optimize the absorption solvent composition and gas-liquid separation process to significantly reduce fugitive; Two-stage alkaline washing tower to reduce the amount of waste liquid and reduce treatment costs.

CO₂ Utilization Pathway after Capture

Energy sector: Oil displacement, fracturing mineralization

Chemical synthesis: Methanol/olefins/carbonates

Industrial applications: Saline wastewater treatment, food-grade CO₂, inert protective gas

Capture-Utilization-Sequestration Integrated Services

Tongxing CCUS Cooperation Model

Equipment Supply

Equipment Supply

Non-standard absorption towers, storage tanks, separators and other atmospheric pressure vessels.

Non-standard desorption towers, drying beds, rectification towers, heat exchangers and other medium and low pressure vessels.

Absorption Solvent Supply

Absorption Solvent Supply

TX-1a High-end absorption solvent;TX-1b Balanced absorption solvent;TX-1c Economy absorption solvent

TX-2 absorption solvent is customized and designed according to customer needs.

Total Solutions

Total Solutions

EPC turnkey one-stop delivery

Implemented 10,000-ton demonstration projects in coal-fired power plants, cement plants, etc.

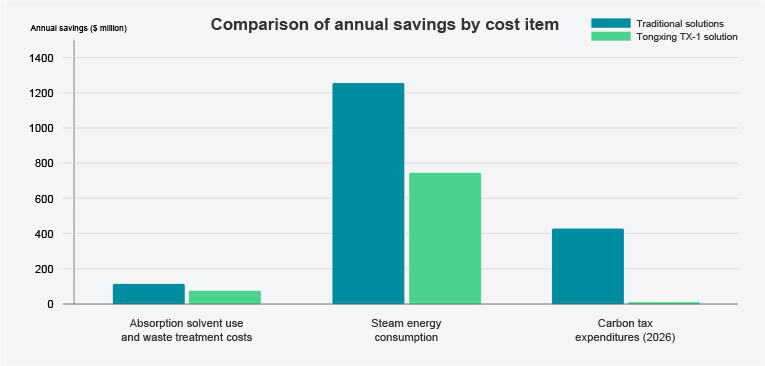

Driving Economic Cost Change in the CCUS

A cement plant with an annual production capacity of 300,000 tons of CO₂ capture is used as a simulation (the specific benefits need to be measured according to the actual scheme and local policies,welcome contact us for a free proposal and precise analysis).

Steam energy savings

(Accounting for 69.8%)

Carbon tax relief

(Accounting for 25.6%)

Absorption solvent savings

(Accounting for 4.6%)

Reduced steam usage

(1.2 tons vs 2 tons of CO₂ per ton)

Annual Net Revenue = (Absorption Solvent Savings $33 million + Steam Savings $504million +Carbon tax savings $184.5 million) = $721.5million

National Green Factory--Creating an energy efficient green supply chain system

Environmental Protection Equipment Manufacturing Base

Absorption Solvent Production

CCUS Equipment Production

Tongxing CCUS Application Cases

- Explore the outstanding performance and core technical data of TX-1 absorption solvent in depth?

- Unlocking the Tongxing CO₂ capture patented technology details?

- Have a comprehensive understanding of the Tongxing integrated CCUS full process service implementation guide?

E·MAIL

PHONE

ADDRESS

Building B10, Binhu Financial Port,

Baohe District, Hefei City, Anhui Province